Master the Art of Soldering Techniques

Share

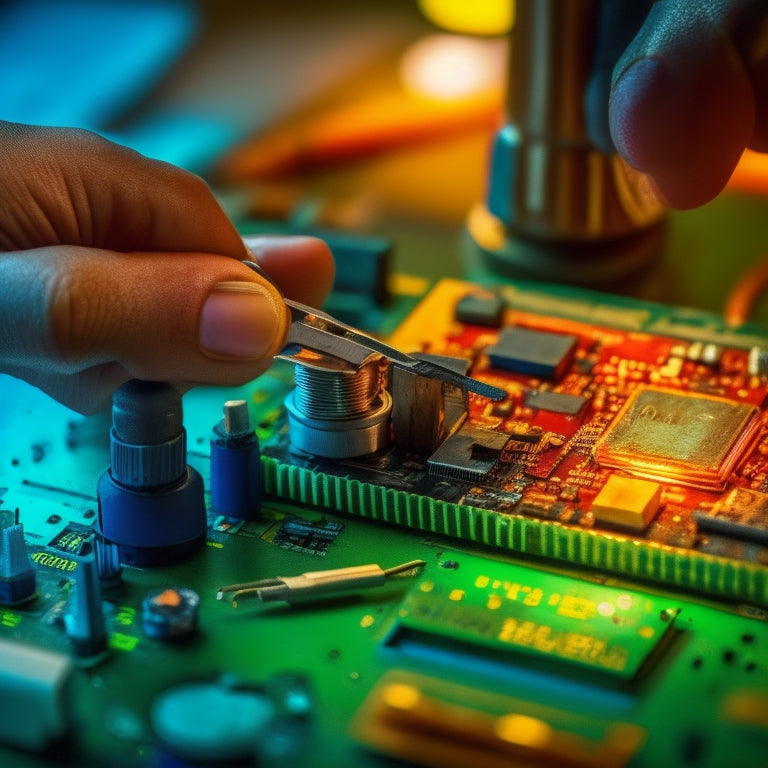

Mastering the art of soldering techniques demands a thorough understanding of fundamental principles, tools, and materials. Mechanical, thermal, and chemical methods are essential techniques to grasp, alongside safety precautions to prevent burns, electrical shock, and toxic fume inhalation. Tool selection and proper use greatly impact joint integrity, with torches, soldering irons, and wire brushes playing important roles. Efficient soldering methods involve prioritizing safety, troubleshooting, and optimizing processes. Understanding material properties, metallurgy basics, and brazing fundamentals is essential for reliable joints. By exploring advanced projects and techniques, one can refine their skills and achieve mastery. A deeper exploration of these concepts can reveal further insights.

Key Takeaways

• Mastering primary soldering techniques, including mechanical, thermal, and chemical methods, is crucial for successful soldering.

• Understanding the properties of solders, fluxes, and base metals is essential for selecting the right materials for reliable solder joints.

• Efficient soldering techniques involve prioritizing safety precautions, optimizing tool selection, and minimizing thermal damage to ensure consistent results.

• Developing skills in micro-soldering, high-temperature soldering, and complex geometries can help take soldering expertise to the next level.

• Proper tool selection and use, including torches, soldering irons, and wire brushes, greatly impact joint integrity and overall soldering success.

Essential Soldering Techniques Explained

Soldering techniques can be broadly categorized into three primary methods: mechanical, thermal, and chemical, each with its unique characteristics, applications, and requirements.

When working with these methods, it's important to prioritize safety precautions to avoid burns, electrical shock, and inhalation of toxic fumes.

Common mistakes, such as overheating, inadequate cleaning, and incorrect flux usage, can lead to faulty joints and compromised structural integrity.

To guarantee successful soldering, it's vital to understand the specific requirements of each technique and take necessary precautions.

Mastering Brazing and Soldering Tools

Beyond the fundamental techniques, having the right tools and equipment is essential to achieving high-quality brazing and soldering results, as the selection and proper use of these tools can greatly impact the integrity of the joints and overall project success. Mastering brazing and soldering tools requires a deep understanding of brazing fundamentals and soldering equipment insights.

| Tool | Description | Importance |

|---|---|---|

| Torch | Used for heating and melting metals | High |

| Soldering Iron | Used for applying solder to joints | Medium |

| Wire Brush | Used for cleaning and removing oxidation | Low |

Efficient Soldering Methods Uncovered

In order to achieve best outcomes, understanding the principles of efficient soldering methods is essential for minimizing thermal damage, reducing production time, and guaranteeing reliable joints.

By adopting efficient soldering techniques, you can avoid common pitfalls and secure consistent results.

Here are three key takeaways to get you started:

-

Prioritize soldering safety precautions: Always wear protective gear, ensure good ventilation, and keep your workspace organized to avoid accidents.

-

Master soldering troubleshooting tips: Learn to identify and resolve common issues, such as cold joints, overheating, and oxidation, to minimize rework and reduce production time.

-

Optimize your soldering process: Streamline your workflow by selecting the right tools, materials, and techniques for the job, and continually monitor and improve your process to achieve best results.

Understanding Soldering Materials Science

The selection and application of appropriate materials are vital to achieving reliable, high-quality solder joints. The properties of solders, fluxes, and base metals greatly influence the soldering process. Understanding soldering material properties, such as melting points, thermal conductivity, and wetting characteristics, is essential for selecting the right materials for a specific task.

Metallurgy basics, including the principles of alloying and phase diagrams, also play a pivotal role in predicting the behavior of solders and base metals during the soldering process. By grasping these fundamental concepts, soldering professionals can optimize their techniques, minimize defects, and produce high-reliability joints.

With a solid understanding of materials science, the art of soldering becomes more predictable, efficient, and effective.

Advanced Soldering Projects and Tips

Sophistication in soldering technique is demonstrated through the successful execution of complex projects, which demand a deep understanding of advanced soldering methods and a keen sense of precision.

To take your skills to the next level, tackle projects that push your limits and challenge your expertise. Here are some pro tips to get you started:

-

Micro-soldering: Master the art of soldering tiny components with precision and accuracy.

-

Soldering irregular shapes: Learn to solder complex geometries with ease and confidence.

-

High-temperature soldering: Develop the skills to work with high-temperature solders and specialized equipment.

Frequently Asked Questions

What Is the Recommended Storage Condition for Soldering Equipment?

When it comes to storing soldering equipment, it's important to maintain ideal conditions to guarantee longevity and performance. A clean, dry environment with minimal exposure to direct sunlight and moisture is recommended.

Store your solder station and accessories in a protective case or cover to prevent dust accumulation and corrosion. Regular equipment maintenance, including cleaning and inspecting components, is also essential to prevent damage and ensure reliable operation.

Can I Use Soldering Techniques for Jewelry Making or Crafting?

A world of creative possibilities awaits!

Yes, soldering techniques can be applied to jewelry making and crafting. In fact, soldering is a game-changer for beading projects, allowing for intricate designs and durable bonds.

Wire wrapping, too, can benefit from soldering, enabling the creation of stunning, long-lasting pieces.

With the right techniques, you can enhance your craft and ignite your creativity.

How Do I Troubleshoot Common Soldering Mistakes or Errors?

When troubleshooting common soldering mistakes, it is crucial to identify the root cause of the issue.

Cold joints, characterized by a weak or incomplete bond, can be caused by inadequate heat application or insufficient solder.

Solder blobs, on the other hand, result from excessive solder or incorrect temperature control.

To rectify these errors, inspect the joint, adjust heat and solder quantities, and guarantee proper cleaning and flux application.

Are There Any Safety Precautions for Soldering in Small or Enclosed Spaces?

When soldering in small or enclosed spaces, safety precautions are paramount. Verify that proper ventilation systems are in place to remove hazardous fumes and particles.

Confined spaces require extra caution, as the risk of inhalation and explosion increases. Wear personal protective equipment, such as respirators and gloves, and maintain a well-ventilated area to prevent the accumulation of toxic substances.

Can I Use Soldering Techniques for Repair or Restoration of Antique Items?

In the world of restoration, where patina and charm reign supreme, soldering techniques can be a game-changer for vintage revival and historical preservation.

Imagine reviving a century-old clockwork mechanism or rejuvenating an Art Deco brooch, its intricate details now shining like new.

With precision and care, soldering can breathe new life into treasured antiques, preserving their essence while maintaining their authenticity.

Related Posts

-

Maximizing Small Closets With Custom Shelving Solutions

You're tired of feeling like your small closet is cramped and cluttered, but with custom shelving solutions, you can ...

-

Effortless Home Organization Systems for Busy Families

You can create an effortless home organization system that caters to your busy family's unique needs and routines. St...